DO's and DONT's of Peptide Solubility

|

For all peptides

|

|

|---|---|

|

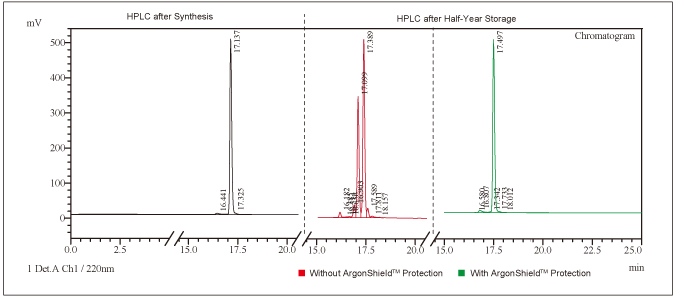

For peptides containing Cys, Met, or Trp residues

|

|

|

For peptides containing Asp, Glu, Lys, Arg, or His

|

|

|

For peptides that must be stored in solution

|

|